The Art of Patterning for Bodywear

Explore our ongoing experiments and be in touch if you are inspired.

-

Our companies are TEF Braids and Tensengral. We use programmable braiding machines with a patterning technology we invented to create functional fabrics and products.

-

Our environmental responsibility is built around low impact manufacturing solutions for products that use unbound, unified filament networks, instead of assembled fabric pieces, to make garments.

-

We practice the art with heritage jacquard circular lace braiding machines that have been updated with CAD and electronic controls.

-

Braiding enables virtually waste-free, efficient manufacture for many different products using scalable, somewhat easy to learn processes.

-

We can manufacture the fabric sized correctly, in one efficient, zero waste step using virtually any thread or yarn combination.

-

Just as valuable as the machines that make the fabric is the way the yarns of the fabric are oriented, meaning how and when they link and interlace.

-

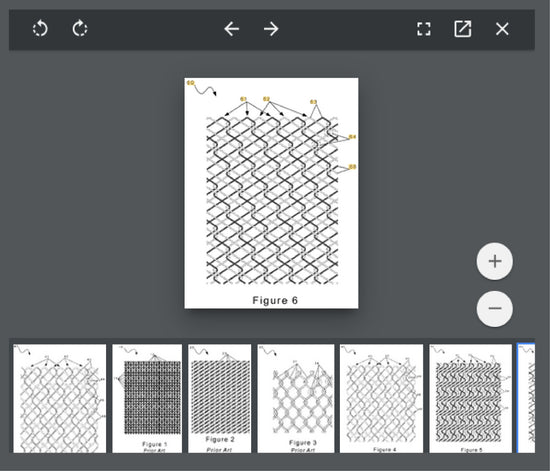

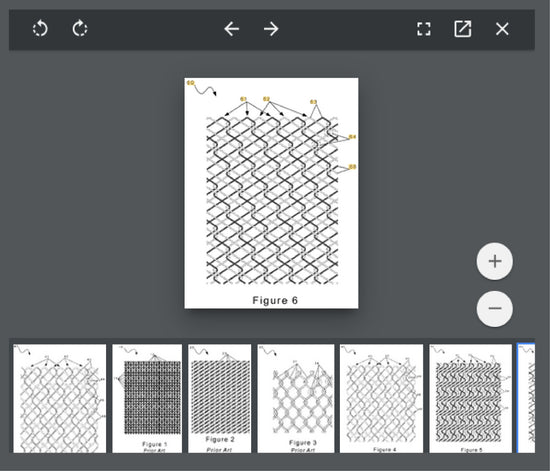

We've described these interlacements in patents that expand the scope and definition of both a braid and lace.

Plexus of filaments with linked members

Patterned plexus of filaments and articles made from patterned filaments.

-

Our patented fabrics unifiy groups of spiraling filaments through links that, when locked out, naturally and magically shape-shift to distribute tensions of motion.

-

The fabric provides a fluid hold with it's textural woven surface. This fluid hold is what makes the fabric so good. No slipping, buckling or rubbing.

-

On-body, the yarns self-organize to become more ‘dense’ in covering/disguising underlying breast tissue for modesty, more open in torso zones where

ventilation is desirable. -

"Almost invisible and quietly supportive"

"The mesh material stays with you and magically adjusts with your movements. -

On-body under tension, the braided structure actually becomes more firm/less extensible for increased support in key zones.

-

We think there's a micro-massage effect, due to the rolling of the fibers as they adjust to distribute tensions -- a really nice thing for underwear.

-

Artisan-designed and individually crafted in upstate New York, USA

-

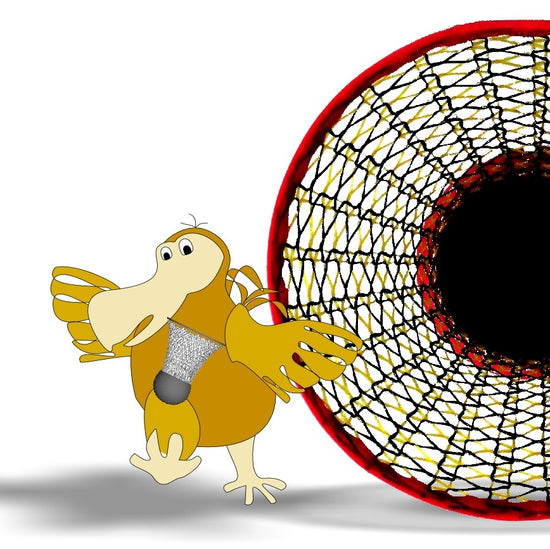

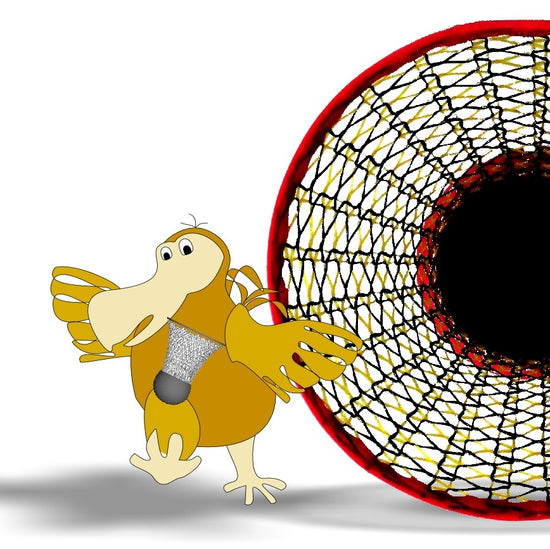

Decades ago we began this braiding innovation when un-successfully seeking a stable, unbound mesh material that was impact resistant and conformal, for a sport product called Birdball.

-

We never would have guessed that a good bit of our life would be spent developing these fabrics, conceiving of products wherein they would be useful and learning the "ins and outs" of these century old machines - crazy indeed!

-

You never know who else might be looking for this sort of material or who we might inspire to think outside the box for apparel design.

-

Contact

ContactLet's find exciting ways to work together and explore the vast potential of this new textile art.